Smart agriculture utilizing IT has been attracting attention as a new-age form of agriculture, and various smart initiatives are underway in the livestock industry as well. One of the front-runners in this field is Urushi no Nakayama, a company based in Kanoya City, Kagoshima Prefecture. Ushino-Nakayama, which engages in large-scale Wagyu cattle fattening, aims to achieve "zero cattle mortality in the fattening process. Amid a labor shortage, the company is working to achieve this goal by using a local 5G and AI-based system for early detection of cattle problems. We spoke with the people involved to find out what they are doing to achieve this goal.

The challenge of "difficulty standing" leading to the death of feedlot cattle.

In the center of the Osumi Peninsula, on the outskirts of Kanoya City, lies Ushinonakayama's Osumi Farm. The farm is about 12 hectares in area (about 2.5 times the size of Tokyo Dome), where about 5,000 Japanese cows are fattened. 42 barns are neatly lined up, giving the farm the appearance of a "cow town.

Scenery inside Osumi Farm

Inside the barn

Although it is hard to tell at first glance, Osumi Farm is actually quite a high-tech farm. Segways are used to transport the staff around the large premises, and all the cattle being fattened here have special sensors in their stomachs. Hideto Yuzuno, the executive officer in charge of DX strategy at Beef Nakayama, explained the situation to us.

This is a system called the 'Gastro Diagnostic Telegraph,' in which wireless temperature sensors are placed in the stomachs of cows to monitor their individual conditions. We use this system to monitor the body temperature of the cows and their drinking status."

The system will be able to detect illness and changes in the physical condition of cows in real time.

The reason why Urushi no Nakayama is so enthusiastic about introducing such high-tech technology is partly to improve cattle quality and partly to cope with labor shortages, but above all because the company is aiming for "zero cattle mortality in the fattening process," as mentioned at the beginning of this article. In conventional large-scale Wagyu beef fattening, it is inevitable that some cattle will die during the fattening process. In the case of the Ushi no Nakayama operation, the cattle mortality rate during the fattening process is about 1%, but the loss of a single Wagyu cow amounts to several million yen, and is a blow that cannot be ignored by the producer. The key to Wagyu fattening is how to detect cattle problems at an early stage and reduce the mortality rate.

The "Gastro Diagnosis Telegraph" was introduced to detect problems in cattle at an early stage, but there was one problem. The cause of death of cows is not always accompanied by a change in body condition.

Cattle have difficulty standing up when they are unable to stand while lying down, which leads to sudden death. Since difficulty standing up directly leads to the death of cattle, we must find it quickly and get them up immediately. Monitoring is very important to prevent difficult standing deaths." (Yuzuno)

Cattle, an animal that lies on its side, may not be able to stand up on its own, and if left unattended, will die in a short time. In order to reliably detect this condition, it is necessary to constantly monitor the posture and movements of cows.

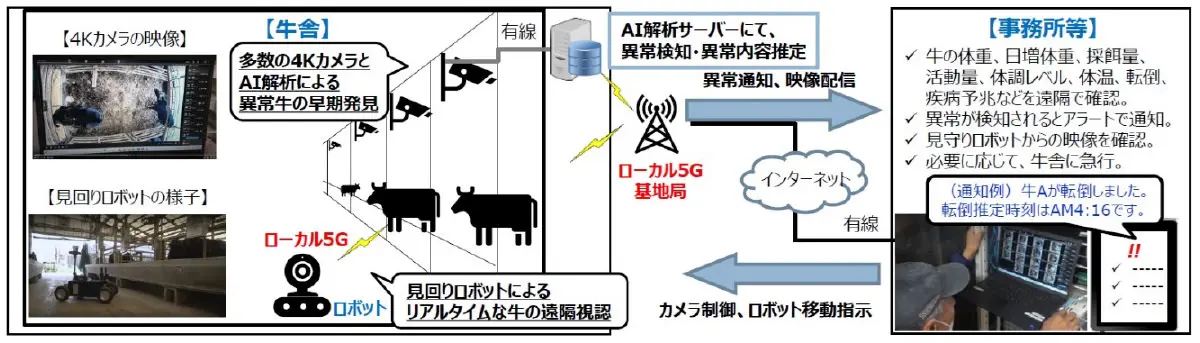

Therefore, in 2022, Bovine Nakayama introduced a system that enables individual video monitoring of each individual cow cell using local 5G, called "Dr. Cow's View," which was built in a consortium with NTT West, Fujitsu, Kagoshima University, and others, utilizing a project subsidized by the Ministry of Internal Affairs and Communications and the Ministry of Agriculture, Forestry and Fisheries. s View" system, which was built in a consortium with NTT West, Fujitsu, Kagoshima University, and others, utilizing a project subsidized by the Ministry of Internal Affairs and Communications and the Ministry of Agriculture, Forestry and Fisheries.

Local 5G to realize a futuristic early anomaly detection system.

In this case, I believe we were able to create an effective system that takes advantage of the high-speed, low-latency characteristics of local 5G."

So says Shinji Nagano of the Kagoshima branch of NTT West, who was in charge of building the system.

Dr. Cow's View, introduced to Osumi Farm, is a system that uses high-definition cameras to monitor the barn 24 hours a day to quickly detect cows suspected of having difficulty standing and notify the manager.

First, 4K ceiling cameras are installed in each of the cattle cells where fattening Wagyu cattle normally spend their time. Although the current system only covers half of the total number of cattle stalls at Osumi Farm, there are still 1,008 ceiling cameras. These cameras take a picture of each cell every 28 seconds, and all the images are sent to an image analysis server installed on the farm. The image analysis server incorporates a dedicated AI that analyzes the large amount of image data sent from the ceiling cameras to determine whether any cows are suspected of having difficulty standing up. If the analysis reveals a cow that is suspected of having difficulty standing, an alert is sent from the analysis server to the staff member's smartphone. Upon receiving the alert, the staff member accesses the overhead camera in the cell where the abnormality was detected from a PC in the management office and checks the condition of the cell using the video images. If the condition cannot be determined from the overhead camera images alone, a command is sent to a self-propelled robot on standby in the farm, and the robot is dispatched to the target cell. Upon arrival at the cell, the 4K camera mounted on the robot takes pictures of the cell from a close range, and the staff checks the images. If the robot determines that there is a problem by visual confirmation, the staff rushes to the target cow cell.

Overall view of Dr.Cow's View

Source: Demonstration of AI image analysis and patrolling robots to improve efficiency in fattening high-quality Wagyu cattle Summary of Results Report

Shelter containing 5G equipment

self-propelled robot

It sounds like something out of science fiction, but this is the system actually in operation at Osumi Farm. Local 5G is installed to cover the entire target barn, and is responsible for data transmission between the image analysis server and the management building, and between the self-propelled robot and the management building. A PC in the administration building is available 24 hours a day, every day, to check images and video sent from ceiling cameras and robot-mounted cameras in real time. All images sent to the control building are transmitted using local 5G, and commands to the self-propelled robots are also sent using local 5G.

Devices to take advantage of local 5G features

The Dr. Cow's View introduced at Osumi Farm was developed using a project subsidized by the Ministry of Internal Affairs and Communications, so local 5G includes a demonstrative element.

This system demonstrated how well local 5G can deliver multiple connections and low latency, and how well it can establish a mechanism to prevent radio leakage so that radio waves don't leak outside the area and cause problems." (Mr. Nagano)

Preventing radio wave leakage outside the area is an important theme when building local 5G, and here LCX (radio wave leakage cable) is skillfully used to prevent radio wave leakage outside the barn. Of the three base stations installed in Osumi Farm, one uses a normal antenna to emit radio waves, but two use LCX.

We had to consider what we could do about it, and we installed LCX cables in two barns to make sure that the signal from the LCX was contained within the barns. We looked at what we could do, and installed LCX cables in two barns to make sure that the signal from the LCX was contained within the barns, and we found this system to be quite effective." (Nagano)

According to Nagano, LCXs are more expensive than regular antennas, but the use of LCXs is likely to be a powerful solution for local 5G deployments in urban areas.

What about the other theme, low latency? Mr. Yuzuno evaluates as follows.

In addition to communication reliability and stability, it is still important to have low latency. we are dealing with video from over 1000 cameras, so Wi-Fi inevitably causes delays and video stoppages. If there is a delay, that delay will cause a delay in responding to the cows. The same is true when checking the condition of individual cows. If the video does not flow smoothly or is not clear, eventually a person will have to go and check it. Using local 5G is a big advantage because we can get stable, clear video."

In addition to the high-speed and low latency features of local 5G, stable communication is very important when using it for real-time monitoring. Local 5G meets all of these requirements, and has proven to provide sufficient communication quality required by Ushino-Nakayama as a line for monitoring operations.

Various introduction effects that go beyond fattening cattle mortality improvement

So, has the system achieved its goals of early detection of standing difficulties and reduction of fattening cattle mortality?

The mortality rate in the demonstration barn (0.51 TP3T) was 581 TP3T less than the 1.21 TP3T rate in the control barn (control). (Nagano)

While the mortality figures clearly show the positive effects of the introduction of the system, according to Yuzuno, the benefits do not stop there. According to Yuzuno, the introduction of the system has also had a significant effect on improving operational efficiency and reducing the workload of staff.

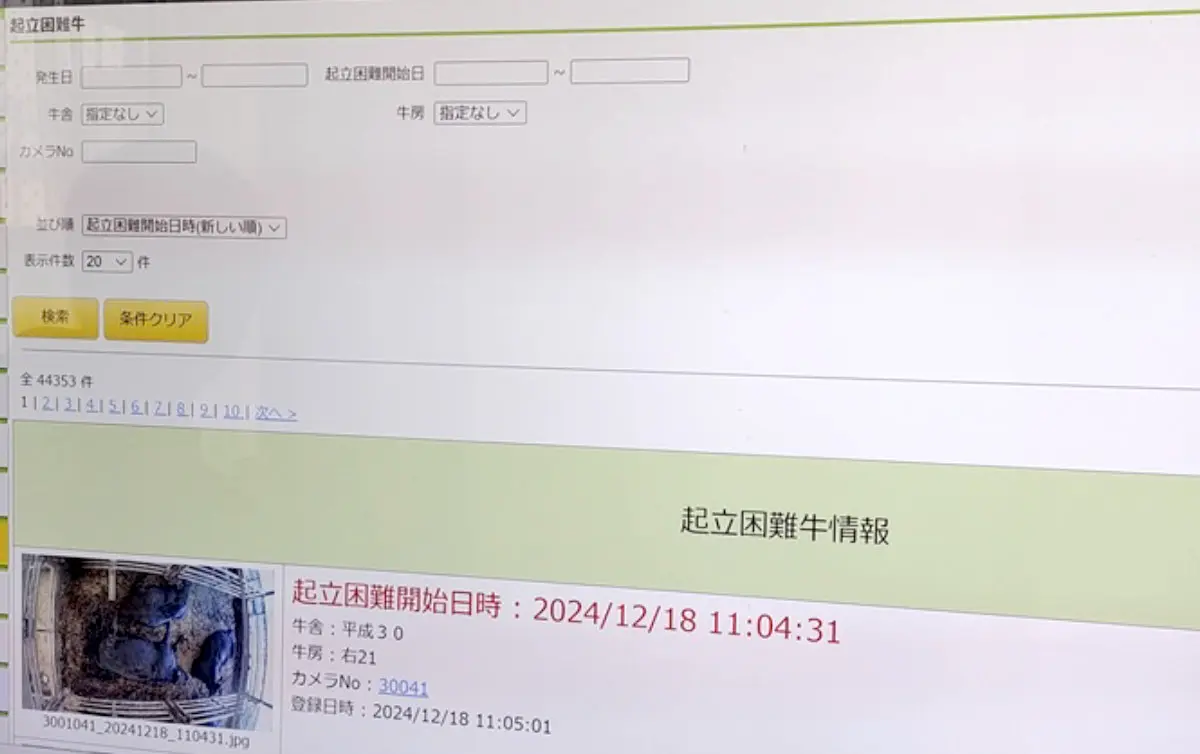

The AI is learning more and more, and the accuracy of its judgment is improving. When we first introduced the system, there were quite a few alert notifications for suspected difficulty standing, but now we have narrowed it down to only the truly suspicious cases. This is important because it also reduces the burden on our staff." (Mr. Yuzuno)

The livestock industry is also in a labor shortage situation, and Osumi Farm also has only one night duty staff. Improving the accuracy of the difficult-to-stand alerts is a major factor in reducing the workload of the night duty staff. In particular, the number of foreign nationals has been increasing recently, and it is very important for them to be assisted by such a system because they are inexperienced in their work, even though they have received training.

Example of Dr.Cow's View screen

Example of recorded image from ceiling camera

In addition, the images and videos of cows recorded by the system are also being used for staff training at Usino-Nakayama, although the system operation of Dr. Cow's View is being handled by Robonet Communications, a local IT vendor that participated in a demonstration project by the Ministry of Internal Affairs and Communications, The company collects the images and videos of cows that have difficulty standing recorded by the system and makes them into educational materials, which are distributed not only to Osumi Farm, but also to the heads of other farms.

A cow with difficulty standing up is one that was normally awake, but then collapses and is unable to stand up. It is difficult for inexperienced staff to judge this. We can't put cows in the difficult-to-stand position for training purposes, so the images and videos recorded by Dr. Cow's View are valuable teaching aids. (Ryusuke Mabe, Robonet Communications)

Even more interesting is the story of how the implementation of this system has also led to the acquisition of new human resources.

When we communicated this system as an attraction to the firm, for the first time in a long time, we had five new high school graduates join our firm." Our next challenge is to build a solid foundation from which we can train new people to use the system." (Mr. Yuzuno)

The introduction of the state-of-the-art system seems to have brought various changes and benefits to the farm beyond the initial goal of reducing fattening cattle mortality.

Expanding Business Development Ideas

Yuzuno is also considering further new business development using this system.

We would like to introduce this system to other farms in our company, of course, but as a next step, we would like to encourage smaller farms in the region to use this system. The system will enable remote monitoring of cattle stalls, so we will be able to take on tasks that cannot be adequately handled by the farmer, such as nighttime monitoring and monitoring of cow births, for example. (Mr. Yuzuno)

Wagyu cattle fattening is an important local industry in Kagoshima Prefecture, but Yuzuno believes there is a need for remote monitoring to reduce the workload, as operators are aging in addition to being short on labor.

So how will Ushino-Nakayama itself secure human resources if requests for remote monitoring services increase? Yuzuno has a secret plan in this regard as well.

We are thinking of having disabled people take charge of remote monitoring from home with the help of organizations for the disabled in the prefecture. We are thinking of getting the disabled organizations in the county to cooperate with us and have them take charge of remote monitoring at home."

While there are initiatives for agricultural and welfare cooperation throughout Japan, the idea of converting jobs that were originally field work into remote work is a novel one. If such novel ideas are added to the use of local 5G, they may serve as a catalyst for a major change in the way people work in the livestock industry and in the industry itself.

The people we spoke with (from left to right: Mr. Nagano, Mr. Yuzuno, and Mr. Mabe)

Possibilities and Hurdles for Wagyu Fattening DX

Bovine Nakayama is promoting the use of ICT, including local 5G, with the aim of making it the "Japanese standard" for Wagyu beef fattening. Therefore, as mentioned above, they would like to encourage other production farmers to use Dr.Cow's View, but there are several hurdles to its widespread use.

One is the awareness of farmers. Many farmers are said to be reluctant to introduce ICT, partly because of the aging of the population. Another is the still high level of difficulty in introducing local 5G.

This time, because we were able to take advantage of the demonstration project, we were able to create an ideal consortium to design and develop the system, but it is not always possible to do things this way. We hope to create an environment where even ordinary farmers and businesses in rural areas can introduce local 5G without difficulty." (Mr. Nagano)

Still, Yuzuno says there is a bright future ahead for this initiative.

Nakayama is a very solid, very nice farm. So it is a very good place to collect data. We are accumulating a lot of data, and I would like to link this to a new business. If we can analyze how each cow was raised, we will be able to predict the quality of the meat in the future, and we will be able to offer a variety of distribution methods, such as pre-order sales and direct connections with consumers, so we will be able to ship more efficiently.

Strengthening food production is an important issue for our country, and Wagyu beef is a promising export product. There are also innovators full of ideas, such as those who have cooperated with us here. Now that it has been demonstrated that the use of local 5G can solve operational issues and improve productivity in Wagyu beef fattening, "one more step" is needed to make the most of this achievement.

*This article was prepared as part of a project contracted by the Ministry of Internal Affairs and Communications.